HAND HELD LASER WELDING MACHIINE

Product introduction

Laser welding is the process of using laser beam as a heat source heating workpiece to weld to melt it to form a welding joint to achieve welding

Laser welding has the following advantages:

(1) The heat input volume is small, the heat affects the area small, and the welding seam deep ratio is large;

(2) Cooling speed is fast, the weld tissue is fine, and the joint performance is good.

(3) Fast welding speed, small welding deformation, high reliability, strong adaptability, good accuracy, high efficiency, easy to achieve automation.

Laser welding can effectively solve problems such as slow traditional arc welding speed, large deformation, and difficulty in employment.

Laser handheld welding equipment is a new generation of laser welding products. It is easy to install and operate simple. It can be used for welding processing. It can be widely used in industries such as kitchen utensils, doors and windows, staircase elevators, stainless steel furniture, hardware sheet metal, advertising, craft gifts, automobile repair, car manufacturing, rail transit, aerospace and other industries;

Equipment Features

*Ecological engineering design: The weight of the handheld is light, the hand feels good, and the operational strength is greatly reduced;

*Safety design: The touch screen button and the mechanical button multi -mutual lock protection, the safe circuit protection (the metal of the air can trigger the light), the nozzle anti -splash anti -high anti -reverse;

*Summit brands: laser, water -cooled machines, electronic components, mechanical structures, etc. are used in international or domestic first -class brands;

*The laser welding system is stable, almost no maintenance, zero foundation is easy to master, no welded certificate;

*Weld spots are evenly distributed, and high -quality light spots required for welding characteristics;

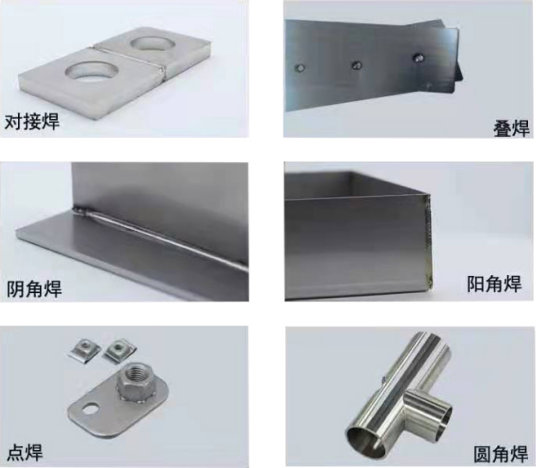

*Suitable for stainless steel, carbon steel, iron, galvanized plate, aluminum alloy and other metal welding splicing;

*Fast processing speed, lower energy consumption, greatly reduce costs, and improve production efficiency;

*Small heat deformation and thermal influence zone (suitable for processing high melting points, high hardness, special materials);

*Performal heat treatment of parts can be performed;

*No noise processing, no pollution to the environment

*Can be combined with robotic arm technology to achieve automation of processing;

*Optical fiber welding tips adopt water -cooled method to ensure the stability of long -term processing laser.

Welding performance

Welding specification

| Laser power | Welding speed (mm/s) | Melving deep (mm) | Welding thickness (mm) |

| 1000W | 15 | 2 | 3 |

| 1500W | 15 | 3 | 4 |

| 2000W | 15 | 4 | 5 |

| 3000W | 15 | 5 | 6 |