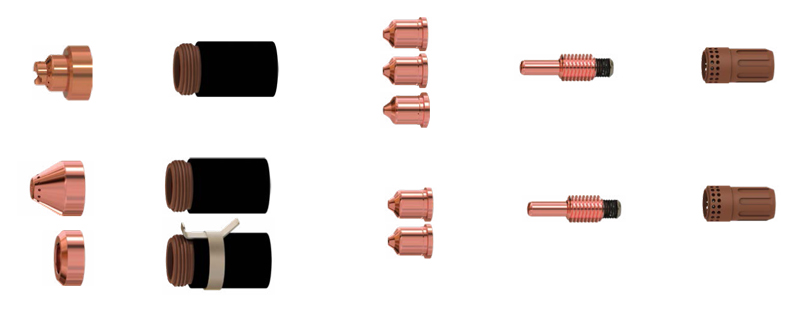

plasma cutting consumables

What are plasma cutting machine consumables?

Plasma cutting consumables are a group of components in a plasma cutting machine that wear out over time until they need to be replaced: they have a life cycle. The wear parts are all in the torch itself, which is where most of the energy is concentrated, and tracking wear is a key part of keeping an efficient machine that cuts well and lasts a long time. Plasma torch wear parts include: a swirl ring, plasma cutter electrode, plasma cutting nozzle, retaining cap and shield cap.

Swirl rings

This is a small part inside the torch that rotates the gas around the plasma arc. This outer layer of gas helps to focus and guide the arc for greater cutting accuracy, while rotating it helps to keep it cool. As the protective layer of gas around the arc comes into contact with the nozzle, the lower temperature prevents nozzle burnout and slows degradation.

Electrode

An electrode is a narrow piece of copper containing hafnium (which is an excellent conductor of electricity). It works by receiving current from the cathode block inside the torch to which it is connected and concentrating the charge through its tip, which causes it to create an arc on the workpiece.

Nozzle

A plasma cutting nozzle focuses the plasma arc and the gas surrounding it to make a clean and precise cut. Nozzles with larger openings are used for air planing, while plasma cutter nozzles with smaller openings are better able to direct the gas and are therefore used for fine, delicate work.

Retaining cap

The retaining cap basically holds all the vulnerable parts of the torch together. Because of the very high temperatures at this end of the machine, it is not just the parts that generate and focus the arc that wear out; the components that hold them together also deteriorate over time.

Shield Caps

A shield cap is used to protect the torch and its other components from the sparks and molten metal generated during the plasma cutting process. It bears the brunt of the impact in order to minimise wear and tear on other components.